By Dachnial Dan Imansyah

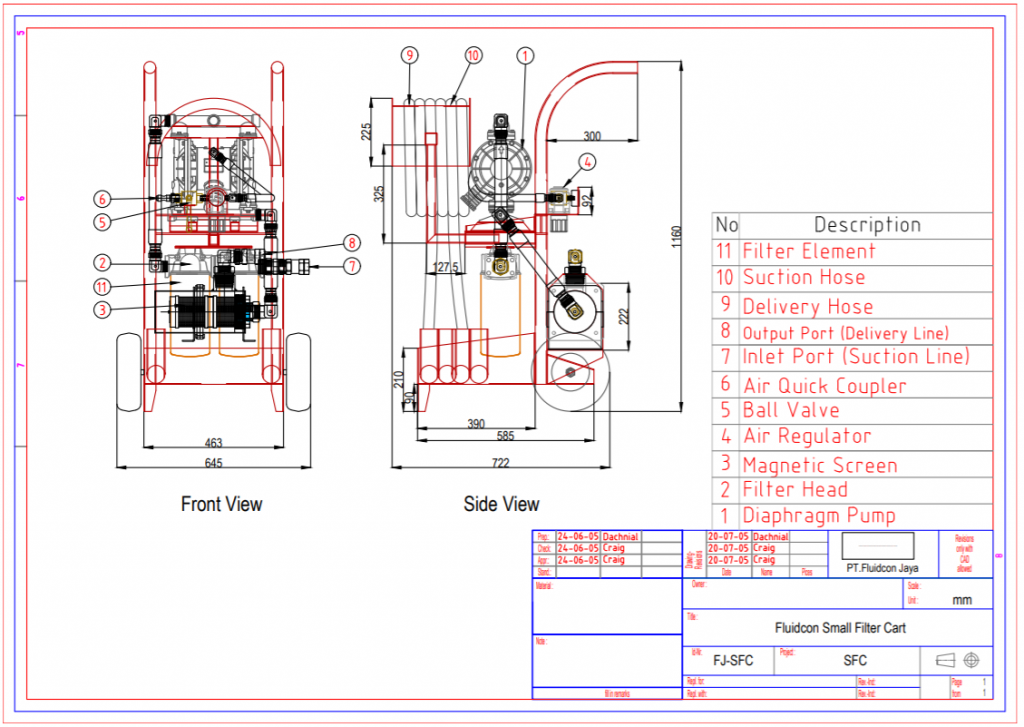

This type of oil filter cart is the same as the large version, but this type is specifically for smaller areas and small fleets. This cart filter uses two oil filters and still uses a diaphragm pump, but is still equipped with a magnetic filter. The shape is small and lightweight, facilitating the mobility of this type.

Below is the functions :

- Filtering and dispensing lubricant and hydraulic oil.

- Contaminate Control – Filter new Hydraulic, Engine, Transmission, and Heavy Final Drive fluid before it enters the equipment.

- Transferring and Filtering fluids from drums to machine.

- Kidney looping fluids on both Small and Large Mobile and Fixed Plant.

- Attaining Desired Contaminate level in your Plant.

Product Advantages :

- Magnetic Screen in pre-pump filtration circuit.

- Incorporates a Non, Filter By-Pass Design.

- Maneuverable and Portable with 10” Pneumatic Tires.

- Incorporates Sample Access Port. Allows for (in operation) Oil Sampling.

- Quick Couplers on cart allow hose maneuverability and a swivel point of hoses and promote contaminate control.

- High pressure rated secondary and final Spin-On filters used.

- Pressure Differential Indicators. 2 by 2 on secondary and final filters.

- Incorporated Pressure Regulator and Pneumatic Control valve.

- Incorporated Spill Tray allows for mess-free filter change and quick access Screen Inspection.

- Capable of filtering high and low viscosity fluids down to desired cleanliness levels.

- Durable, Tough Low maintenance Self Priming Pumping System.

- Pumping and Filtration Speed Adjustable.

Main Equipments

Diaphragm Pump

Graco Husky 1” with 1: 1 ratio pump is an air-operated double diaphragm pump, and capable of delivering a free flow of 160 liters per minute (lpm), due to the fine micron filtration of the filters and the viscosity of the oil. Nevertheless tests while pump 15w/30 weight oil has shown flow rates up to 30 lpm have been gained.

The flow rate will fill an empty 200-liter drum in 7 to 8 minutes, and the same time is required for one cycle of the kidney loop. The number of cycles through the kidney loop to achieve specified cleanliness is dependent on the initial condition of the oil and the filtration effectiveness.

Main Line Filtration

The primary filtration process is the Magnetic Screen Filter with a standard mesh of 100 microns. It Contains 2 (two) magnets with polarizing steel end plates and 3 (three) wire cloth elements. The secondary filtration process is 11 microns of Donaldson filter element and the Final filtration process is 5 microns of Donaldson filter element with Pressure Differential Indicators.

Air Regulator and Control Valve

Pumping speed is controlled by a 1/2“ Pressure Regulator and Pneumatic Control valve with a Pressure Gauge.

Sample Access Port

Incorporates Sample Access Port. Allows for (in operation) Oil Sampling.

OPERATIONAL INSTRUCTIONS

Pre-Start

Pre-start starting Checks.

Before starting, please check the following instructions :

- Ensure Pneumatic connections from airlines and Small Filter Cart are securely attached. Unit is supplied with a Parker 2F Air Quick Disconnect Coupler.

- Check inlet and outlet hose and fittings are securely connected.

- Check the filter elements, make sure that they are fit enough into the filter heads.

- Check the suction and delivery lines, make sure all lines are fitted already to the sources. Use proper quick-disconnect couplers for easy operation and to avoid oil spillages.

Operational

Oil is to be circulated through the kidney loop filter system until the specified cleanliness is achieved. To filter the oil proceed as follows :

- Position the small filter cart air control ball valve to OPEN position.

- Open the air control ball valve smoothly.

- Set Air Regulator to 30 psi by pulling black control knob down, one click and rotate clockwise to increase or anti-clockwise to decrease to appropriate pressure to attain desired flow.

- The diaphragm pump should be heard operating.

- Visually check the pressure differential indicator on each filter head, make sure the ball is not reaching the red indicator.

- If the ball is reaching the red indicator then slow down the air pressure by adjusting the air regulator and air control ball valve.

- If the Pump continues is running at a slow speed and the ball is still reaching the red indicator, this indicates the filter element is blocked and requires replacement.

- If the oil is cleaned to specification :

- Switch the Small Filter Cart airline control ball valve to the OFF position.

- Switch the airline source to the CLOSED position.

Initial Design